Valdor's Impact Mount® fiber optic connector line (IMT) is all-mechanical and field installable.

It offers long-term usage with minimal repair or replacement, and is suitable for harsh environments.

These connectors contain NO epoxy or index matching gel typically found in other mechanical connectors available on the market.

The mounting concept is based on dynamically compressing metal ferrules uniformly around optical fibers creating a hermetic seal.

The unique features of the IMT connectors provide stable readings with little variation even in harsh environments.

Field termination is quick and easy. The Impact Mount®

Termination Hand Tool is universal and can be used for all types of IMT fiber optic connectors including LC, ST, SC, FC, SP, and SMA.

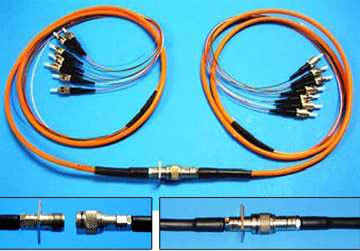

HEPTOPORT® RMC Rugged Multi-Channel Connector

Impact Mount® Technology Concept

The mounting process is accomplished in three steps:

The mounting process is accomplished in three steps:

- Impact Mount tool dynamically compresses the metal ferrule tip around the fiber

- Crimps buffer at the rear of the connector

- Polishes end of ferrule in 20 seconds

TECHNICAL SHEETS:

Product Specifications

Product Specifications

Valdor’s rugged HeptoPort® RMC multi-channel connector is part of the

HeptoPort® product line that utilizes the breakthrough two dimensional (2D) self-alignment concept:

a technology that enables an optical connector to be aligned with a rotational alignment key such that when

2 multi-channel connectors are mated, all 7 fibers will be automatically aligned. This connector is designed

specifically for harsh environments and is ideal for aerospace and military applications.

HeptoPort® products offer the highest density per surface area to interconnect optical fibers

in the field with significant cost savings. Valdor also offers HeptoPort®

multi-channel connectors in a variety of custom configurations, such as the HeptoPort®

7-Fiber FC connectors.

- High Density Interconnection

- Low Insertion Loss

- Harsh Environment

- Significant Cost Reduction

- Aerospace

- Military

- Offshore Oil drilling

- Mining Application

- Optical Sensors

- Medical Application